2020-12 Brexit Re-Application

In our first December, we didn’t have a lot of clothing or equipment to enjoy the conditions outside, so focused indoors on house repair tasks and emigration-related tasks.

Due to the UK exit from the EU, we had to re-apply to stay in Sweden. There are some specific terms that apply but I will keep the description light. In theory, it should have been no problem as we had already gone through the process in July. As a result, we had been accepted onto the population register and as a result, received a unique tax reference (“personnummer”). The public statement was that those that still qualified would have no issue. The paperwork stated that no evidence needed to be resubmitted from the previous application.

Brexit Emigration Re-application

This ended up being stressful over the months to come. Despite any guidance, It became apparent that they wanted all the original evidence again. The handler wouldn’t reply to emails but would send individual requests for evidence about a month apart. We were also still having issues with postal delivery. For the next few months, we would get letters giving a demand for a specific bit of evidence. We would have 10 days to reply, but the letter would arrive on day 8. It caused a lot of anxiety. We would constantly be checking the postbox in case of the need to rush to supply some evidence. Although we had no car, we had to keep the driveway clear of snow so the post could be delivered.

The process dragged on and the whole time we didn’t have certainty as to if we should be investing in the house or not. We didn’t have confidence in the process. Online, there were stories of inconsistencies. For example, where private medical insurance from a specific company was usually accepted, but sometimes the same policy was rejected for others. This made us more nervous and it was hard to know if we should be making long-term plans or were at genuine risk of being removed. It added a layer of stress to all the normal problems that you face in life.

Eventually, it became apparent we were being re-assessed using different criteria to the original application. We had to prove what our income and taxes were, which was more difficult than normal because we had not completed our first year in the Swedish tax system.

Pepparkakshus

I sent each of my family members back in the UK a gingerbread house (Pepparkakshus) kit. Making these houses is a Swedish tradition for Christmas. Interestingly, the kits were manufactured in Manchester in the UK. Sadly the kits got pretty demolished in the post, but the family posted up some entertaining repair attempts.

Dangerous Tree

There had been some strong and gusty winds. I realised that a large tree near the footbridge had snapped its trunk, but stayed upright. This meant it could fall over at any time. In the UK this would be a safety and legal liability. However, the tree was on a riverbank which I know in the UK can cause some complex legal issues. So I contacted the local council (Kommune) to check the law and any local rules. The kommune are normally helpful but I received an uncharacteristically aggressive member of staff. The legal questions got ignored. He denied any kommune presence next to the footpath, stream, or the largest road in Sweden. Multiple neighbours later said it is better just to get on with things and do a good job.

My neighbour is a farmer and he came to help. He used straps and winches to remove the dangerous tree without it falling on the local path, bridge or themselves. It was really tricky to work on as the tree was in an awkward location. He did a fantastic job.

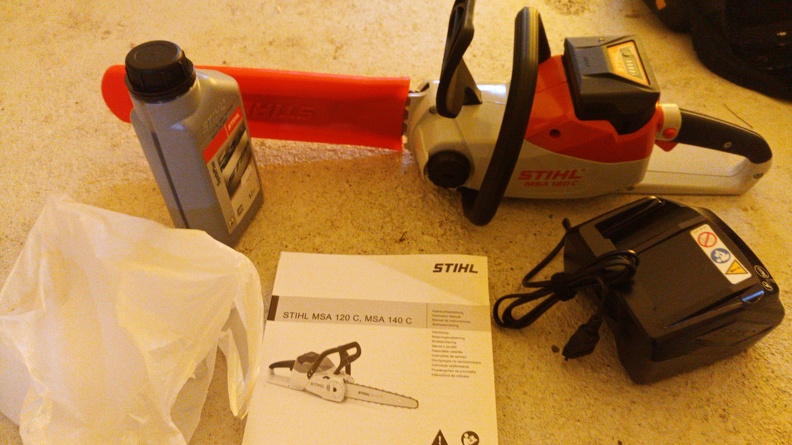

I invested in a small chainsaw for general work and to cut up the remains. I went for a battery one which was not a popular choice with local friends, but I think is safer. It stops faster than a petrol saw and makes a lot less noise. As there is less noise it is easier to keep awareness of others around you when working. There is not much choice in blade length with the models that use this battery range. I also liked being able to buy it from the local hardware shop as I wanted to buy more locally.

Winter Plants

The plants growing under growlights in the garage were still doing ok. The constant odd lights in the garage did get noticed by the locals who gently queried what I was growing. I was a bit disappointed that the police didn’t arrive to inspect my fantastic Parsley. It would have made a good photograph. Maybe the growlights are a bit underpowered but we were successful in getting a crop. Watering was a problem and we lost plants from forgetting to go out in the snow to the garage.

Food Cellar Door

A door separated the old basement “heating room” from the food cellar. As the heating room once had an oil burner system in it, it had been previously fireproofed. The ceiling was covered in cement board and the door had a metal plate over it. It was pretty sooty and oil stained and a challenge to clean.

My idea was to paint it with a thinners-based paint that could cope with the soot and oil. I painted the food cellar metal door cover with a special metal primer. However, I had not accounted for the old central vacuum system pipe work terminating in this room. The pipework passively delivered the fumes directly to our bedroom on the top floor of the house. It was not a good nights sleep.

When dry it didn’t look like a great door to paint. Instead of looking like a farmhouse, it looked like a wartime bunker. I did not like having wasted money on painting but sometimes you have to try things to realise they won’t be what you wanted. I removed the metal cover on the door. There was a beautiful wooden made door underneath.

Food Cellar

The food cellar in the basement had a large crack all the way around the three outward walls; I later found out from the previous owners that this occurred once during heavy rains one year. The floor in the food cellar was also broken with a lot of dust and creatures in the room. I discovered two mice had got in through the air vent but had died after not being able to escape. The room was not useful for storage until repaired so I started making plans for how to make the repair.

The general consensus among builder friends and family was to clean and plug the cracked concrete with a strong repair product. If the crack reappeared it would be an ongoing problem or ignorable. I used a hard concrete repair product (Husfix). I cleaned the cracks but the old concrete was crumbly. So I made a watery mix of Husfix, slightly thicker than paint, and applied it to all the surfaces like a primer. I let it set and then applied a normal thicker layer to the solid surface. After this, I used Husfix on the wall surface like plaster. I know people prefer Lime for this but I couldn’t get any at the time.

I put a metal grill over the air vent to stop mice from coming in. This would later turn out to be a mistake as the metal caused condensation and ice to form on the vent, and created a damp spot on the wall beneath. The discolouration from this is visible in the photo above. Later I replaced it with a metal mesh on the far outside surface and a plastic vent inside.

Research

The budget this month was for various tools and supplies I thought I might need for this project, and watched lots of Americans on YouTube laying small concrete floors.

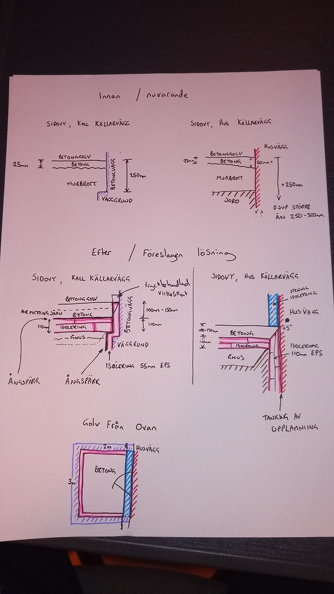

I then tried to make different plans and show them to my different building trade friends. It was hard to work out a good solution to prevent cold bridging of the cold-cellar slab to the house foundation.

I researched the building regulations during the planning. Once I had the final plan for the slab, I contacted the local building control who politely told me to go ahead and repair the floor. I think sometimes I worry too much.

Other Basement Work

I also started work on making the general basement more usable. It had a rough concrete wall finish, like on the side of a breezeblock. There were a lot of spiders and other creepy crawlies. I repainted the floor with water-based floor paint to seal in the dust and put a hard thin cement product (Husfix) over the walls as a render.